Simple, professional layout design

Reliable control

Licensing without expensive update costs

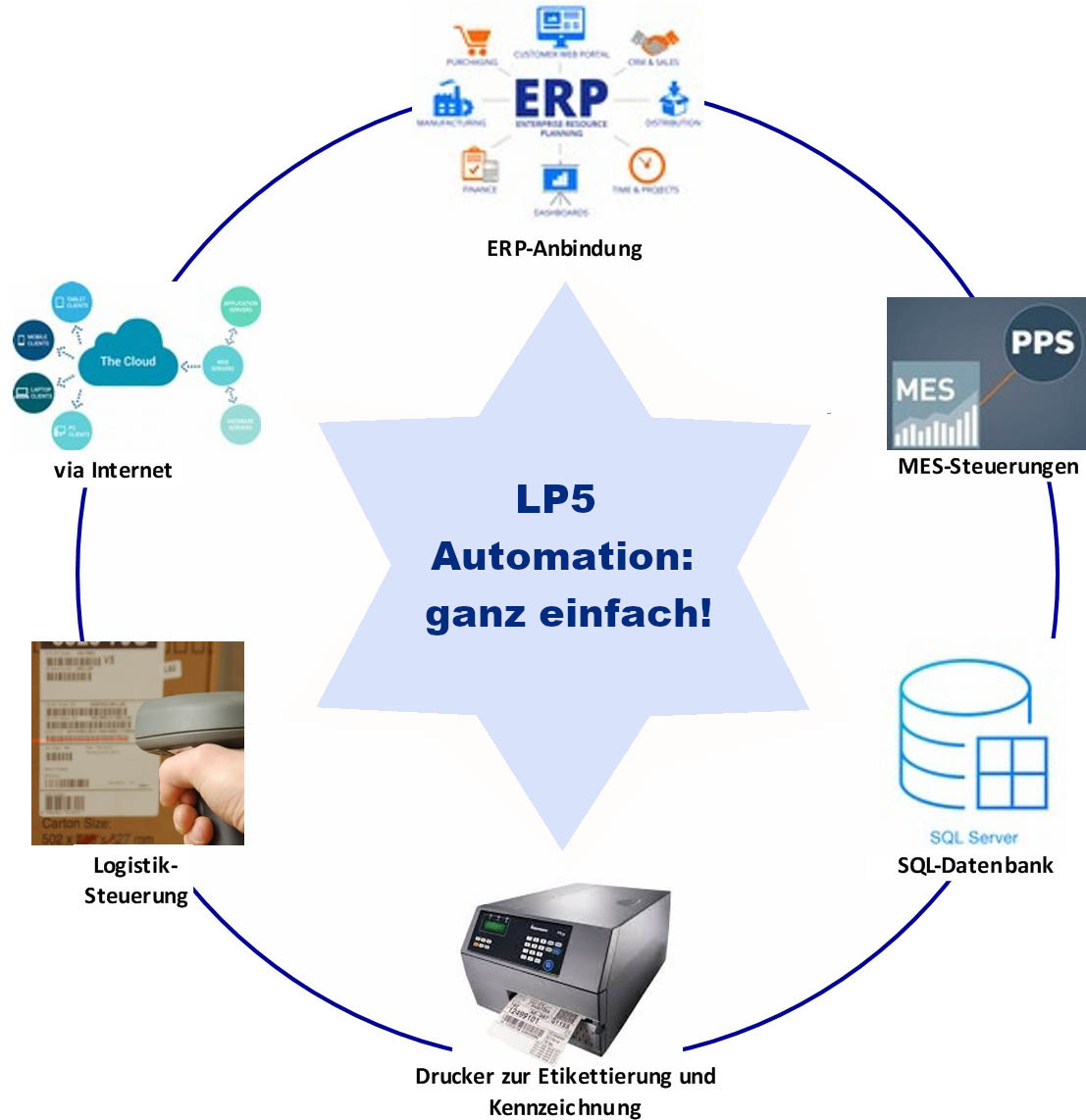

Automatic data exchange

Simple software integration

Transparent installation

OUR SPECIALITY FOR YOU

INTEGRATION INTO PRODUCTION PLANTS

Our speciality is the integration of complete labelling and control systems in production plants controlled and monitored via Windows or Linux-compatible software and PLC.

Labels Platform LP5

We have been successfully using LP5 software with our customers for many years. Flexible, lean, powerful software. Sole agency Switzerland – more than 200 licences for LP5 are in daily use in Switzerland.

NIcelabel

With the NiceLabel software:

The easy way – error-free and reliable.

THE INTELLIGENT FACTORY – GO ONE STEP FURTHER WITH US

OPC UA – OPEN PLATFORM COMMUNICATIONS – UNIFIED ARCHITECTURE

Cross-machine interaction, control and exchange of production-relevant machine data. Machine data from sensors, devices and software such as measured values, parameters or control variables are stored in the cloud as OPC UA protocols (standardised data model / interface standard) and used by a higher-level control system across machines between printers, robots and IT systems from different manufacturers.

OPC UA is de facto the new standard for Industry 4.0 and IoT (Internet of Things). Conditions:

For example, the cab label printers Hermes Q, SQUIX, EOS and the IXOR label dispenser sold by us.