FROM STACK TO STACK

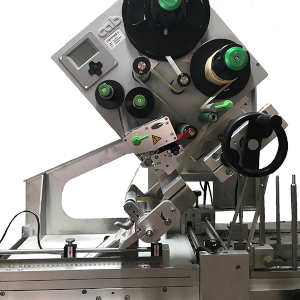

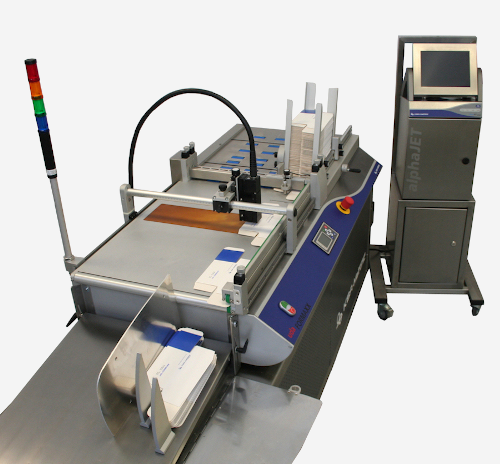

OFFLINE PRINTING SYSTEM udaFORMAXX

Stand-alone solution for offline labelling separate from the production line.

Used for small to medium batch sizes, for example for:

Industries

1. separating

2. labelling

3. checking (optional)

4. sorting out (optional)

5. stacking

with upper belt = intermittent (+ continuous) operating mode

udaFORMAXX “c”

with wide conveyor belt = continuous operating mode

Use for small to medium batch sizes, for example for:.

Industries

1. separating

2. labelling

3. checking (optional)

4. sorting out (optional)

5. stacking

with upper belt = intermittent (+ continuous) operating mode

udaFORMAXX “c”

with wide conveyor belt = continuous operating mode

Very descriptive

explanatory video for the use of the

udaFORMAXX

udaFORMAXX-FEEDER

PRACTICAL EXAMPLE

Labelling of block bottom bags

The stack-to-stack print & apply system was designed, installed and commissioned by SIGTECH AG at the customer’s request, assembled and commissioned.